Product Description

The PVC Layflat Fire Hose Making Machine/Production Line is engineered for high-efficiency production of flexible PVC hoses. With components like a single screw extruder, haul-off machine, and winder, the line simplifies production and reduces costs. It’s perfect for civil engineering, irrigation, and garden hose applications, with adaptability to different hose sizes using matched extruders and auxiliary equipment. Designed with high-strength compounds, it guarantees a long lifespan and pressure resistance.

Advanced PVC Hose Extrusion Technology

Our PVC Layflat Fire Hose Making Machine/Production Line is an advanced system tailored for manufacturing flexible hoses that meet both low and high-pressure requirements. The process involves a single screw extruder, custom molds, a vacuum water tank, and an efficient haul-off system, delivering consistent quality and ease of operation. By combining PVC and polyester fibers, the machine produces durable hoses that resist internal and external pressures, ideal for various industries including agriculture, shipbuilding, and civil engineering.

High-Strength and Long-Lasting PVC Hoses

The PVC Layflat Hose Extruder produces hoses with rich flexibility and robust impact resistance, suitable for vinyl greenhouses, construction projects, and water drainage systems. The integrated extrusion process blends high-strength compounds and polyester fibers, ensuring the hoses retain their structure under extreme pressures. Additionally, the opaque hose design prevents moss and microorganism growth, making it a long-lasting product that's easy to install.

Optimized for Versatile Applications

This PVC Water Hose Production Line supports multiple applications such as irrigation, drainage, and water supply, offering tailored solutions based on customer specifications. The water tank, haul-off machine, and winder guarantee precise hose production, while the winder ensures storage in uniform lengths. The machine is suitable for producing both universal low-pressure hoses and high-pressure PVC water hoses, making it a versatile option for businesses looking to expand their hose production.

Product Application

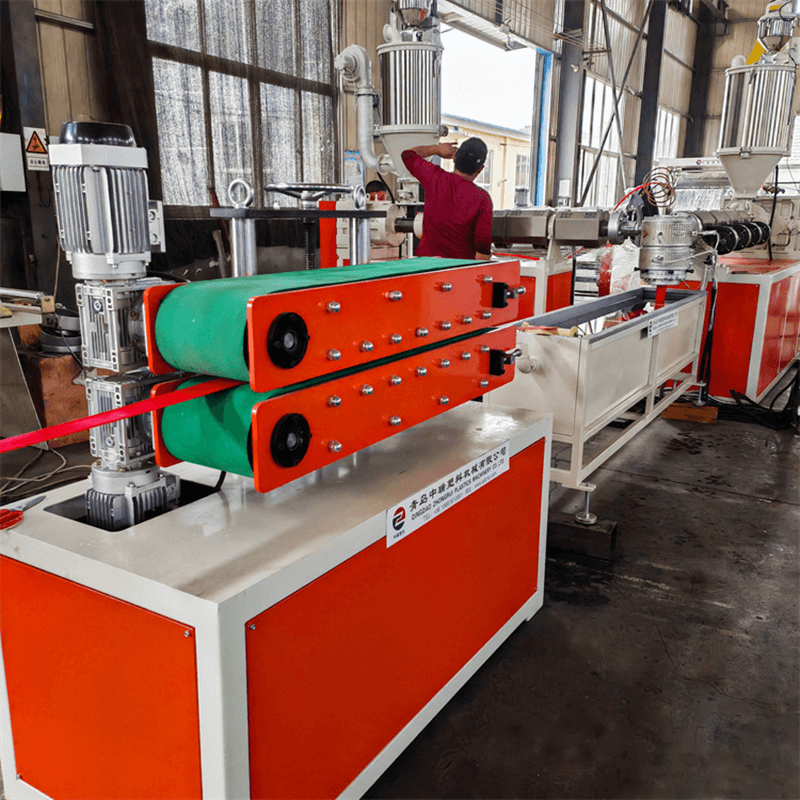

This flexible hose is a simple extrusion line, consisting of a single screw extruder, custom moulds, water tank, haul-off machine, and winder. Designed for easy operation and low costs, this machine is widely used in irrigation and gardening. Depending on the customer's required hose dimensions, we provide the suitable extruder model and auxiliary machines for optimal production.

|

Model | | | |

| | | |

Cooling water(m3/h) | | | |

| | | |

Overall size(L*W*H)(mm) | | | |

Weight(kg) | | | |

The purpose of PVC Water Hose Production Line

Used in civil and construction engineering, agriculture, shipbuilding, and fisheries

Universal low-pressure sprinkler and high-pressure water supply and drainage

Used for vinyl greenhouses and stables

Features of PVC Water Hose Production Line

Easy to Operate: Simple extrusion setup with a single screw extruder and low operational costs.

Durable Construction: Made with high-strength compounds, offering excellent resistance to pressure and impacts.

Long Lifespan: The machine produces hoses with enhanced durability, ensuring extended use.

High-Performance Design: Equipped with an advanced haul-off machine and a winding system for efficient production.

Customizable: Adaptable to different hose dimensions with matching extruder models.

Structure of PVC Water Hose Production Line

The line injects high-strength polyester fibers into a specialized PVC hose and blends them together, ensuring the inner layer does not separate from the external coating. Thanks to this manufacturing process, the hose is capable of withstanding high internal and external pressures, making it suitable for both low-pressure and high-pressure applications.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province