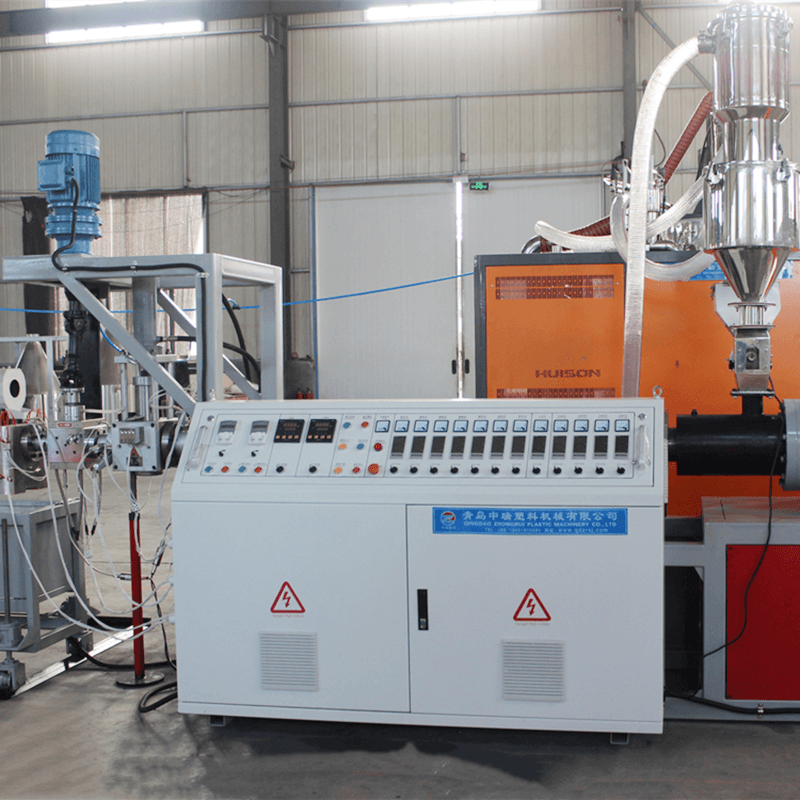

This Multi-functional Energy-efficient PET Strapping Production Line offers versatility, enabling the production of up to 6 straps simultaneously. With high-output extrusion, it supports both recycled PET scraps and granules. Complete with a fully automated PLC system, metal pump stability, and an automatic flushing filter, this line guarantees reliable, continuous operation for businesses aiming for both quality and efficiency in their production processes.

High-Efficiency Strapping Production

The Multi-functional Energy-efficient PET Strapping Production Line is engineered to maximize productivity while minimizing resource consumption. Its advanced single or twin screw extrusion technology caters to varied material conditions and production requirements. With an extrusion capacity of 1-6 straps, this line ensures efficient, high-volume output.

Energy-Saving and Eco-Friendly Design

One of the standout features of this system is its energy-saving oven design, which significantly reduces power consumption. By utilizing 100% recycled PET scraps or granules, the line aligns with environmentally sustainable production practices. The automatic flushing filter screen and metal pump contribute to stable, continuous production, ensuring a reliable output without interruptions.

Fully Automated for Ease of Use

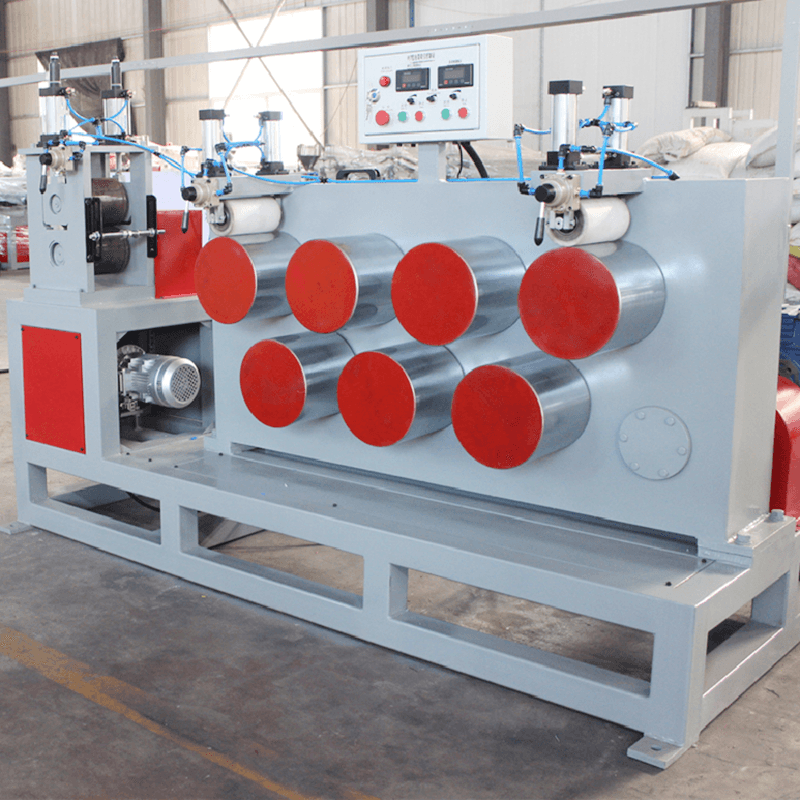

Thanks to PLC-controlled automation, the entire production process is simplified and streamlined, reducing the need for manual intervention. This strapping production line is also equipped with servo or torque motor winding machines, ensuring precise winding for both manual and automatic PET straps. The system can also produce monofilament by changing specific parts, making it a flexible solution for various production needs.

Product Features

Compact design for space-saving and high-output efficiency.

Twin screw extruding technology for stable and even plasticization.

Compatible with 100% recycled PET materials, supporting eco-friendly production.

Fully automated system with PLC control for precision and stability.

Produces 1-6 straps simultaneously based on customer requirements.

Servo and torque motor options for winding machine customization.

Energy-efficient operation, reducing power consumption.

Equipped with an automatic flushing filter screen to ensure smooth, continuous production.

Capable of producing monofilament for diverse applications.

Main parameters of PET Strapping Band Production Line

| Model | 65-1 | 75-2 | 90-2 |

| Band number | One | Two | Two |

| Band specification | 9~19mm(Width)

0.5-1.50mm(Thickness) | 9~19mm(Width)

0.5-1.50mm(Thickness) |

| Output | 50kg/h | 100kg/h | 150kg/h |

| Water flux | 0.6 m3/h |

| Water pipe diameter | 3/2″,water temp according PET strap size |

| Compressed Air flux | 0.25 m3/min |

| Compressed Air pressure | 0.6Mpa |

| Total Power | 132kw | 186kw | 285kw |

| The length of production line | 25-28m | 28-33m | 35-40m |

| Power | 380V 50HZ or Customized |

How to Maintain

Regularly clean the automatic flushing filter screen to ensure uninterrupted operation.

Periodically inspect the metal pump and ensure it is properly lubricated to maintain stable production.

Follow recommended service intervals for the winding machine motors (servo or torque) to prolong operational life.

FAQs

Q: What materials can this machine use?

A: The machine can use 100% recycled PET scraps, virgin PET materials, or a combination of both.

Q: How many straps can the machine produce simultaneously?

A: The machine can produce between 1 to 6 straps at the same time, depending on customer requirements.

Q: Is the machine fully automated?

A: Yes, it is equipped with a PLC-controlled system that manages the entire production process with minimal manual intervention.

Q: Can this machine produce different types of straps?

A: Yes, it can produce both manual and automatic machine straps. Additionally, it can produce monofilament by adjusting some parts.

Q: Why choose us?

We have 20 years experience for producing machine.We can arrange for you to visit our local customer's factory.

Q: Delivery time

20~30 days

Q: Payment terms

30% of total amount should be paid by T/T as down payment, the balance (70% of total amount) should be paid before delivery by T/T or irrevocable L/C(at sight).

Q: Warranty

1 year

The Packaging Belt Production Line by Zhongrui offers a robust solution for high-speed PET and PP strapping production, ensuring durability, energy-efficiency, and exceptional tensile strength—perfect for the packaging industry.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province