Waterproof Drainage Board Production Line for Construction Applications

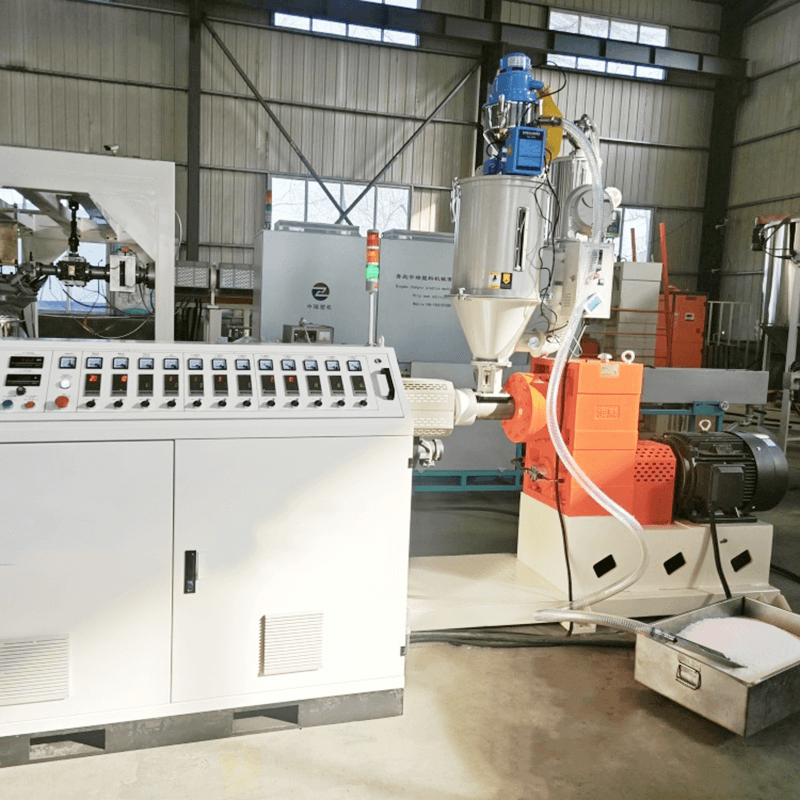

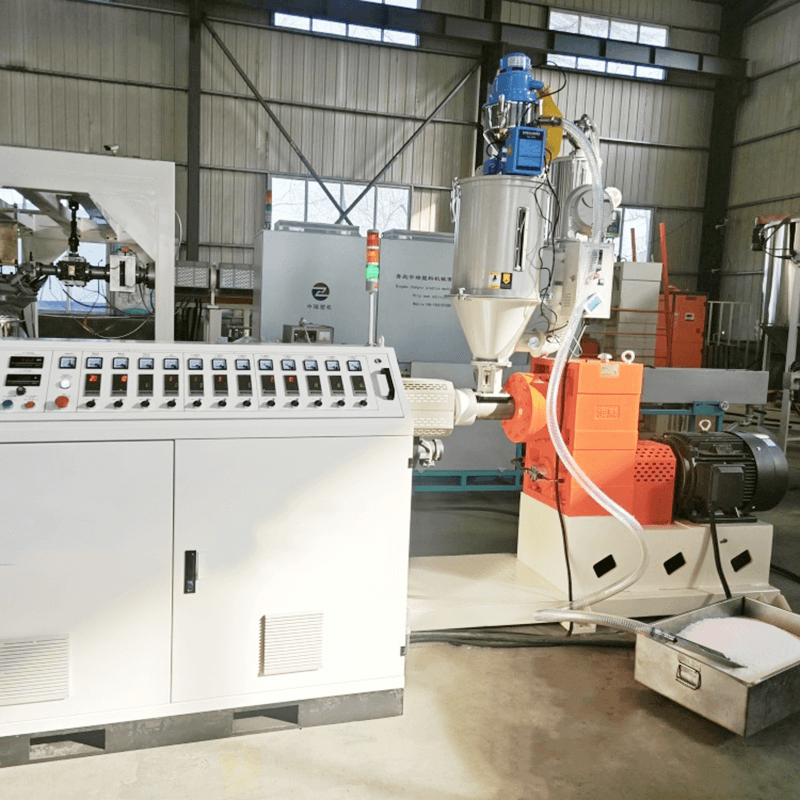

Qingdao Zhongrui Plastic Machinery Co., Ltd. is a professional manufacturer and supplier of the waterproof drainage board production line. This equipment is designed for large-scale production of drainage boards used in construction, landscaping, and waterproofing applications. It ensures high efficiency and stable output for industries requiring effective water management solutions.

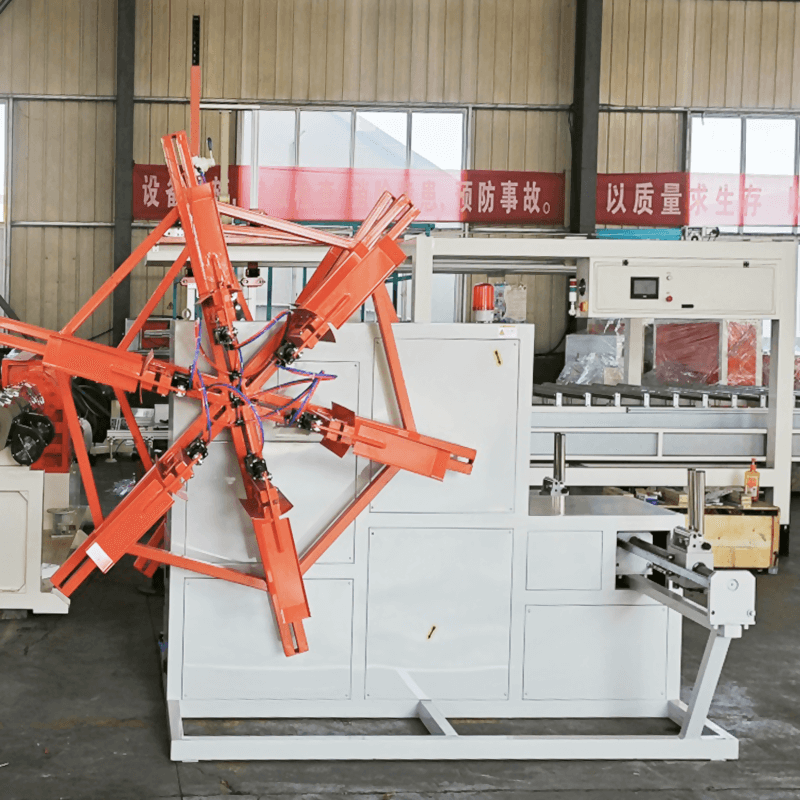

The machine includes an extruder, forming unit, cooling system, automatic cutting unit, and intelligent control system. The single-screw extruder enables continuous extrusion with precise speed control. The production process supports various materials, including HDPE and PP, ensuring strong and durable drainage sheets for long-term use.

This plastic drainage sheet extrusion machine features full automation with an advanced computer control system. It is equipped with a Siemens inverter for accurate operation. The screw, made of 38CrMoALA, provides excellent wear resistance. The machine operates at 380V, 50Hz, with customizable power configurations.

As a trusted drainage board manufacturing equipment supplier, Zhongrui offers complete installation support, operator training, and a one-year warranty. Customization options are available to meet specific industry needs.

Technical Specifications

| Parameter | Value |

| Material | HDPE, PP |

| Color | Black |

| Extruder Type | Single-screw |

| Screw Length-Diameter Ratio | 33:1 |

| Screw Rotation Speed | 55 rpm |

| Automation Level | Fully automatic |

| Control System | Computer-controlled with Siemens inverter |

| Power Consumption | 11kW |

| Voltage | 380V, 50Hz, three-phase |

| Machine Weight | Approx. 1000kg |

| Screw Diameter | 45mm |

| Screw Material | 38CrMoALA |

| Raw Material | PE Granules |

| Production Type | Continuous extrusion |

| Customization | Available |

| Warranty | 1 year |

| After-Sales Service | Free installation, training |

This waterproof board production supplier ensures high precision and efficiency in every unit. The automatic drainage sheet machine is ideal for producing geocomposite drainage board solutions for multiple applications.

Key Features of Waterproof Drainage Board Production Line Equipment

Efficient Extrusion Process

The drainage board production line uses a high-precision single-screw or twin-screw extruder. It ensures uniform melting and stable shaping of materials like HDPE and PP. This process enhances the strength and durability of the final product.

Advanced Control System

A fully automated system with a PLC touchscreen allows easy operation and monitoring. The Siemens inverter enables precise speed adjustments, ensuring consistent production. The control system minimizes manual intervention and improves efficiency.

Customizable Molding Options

The production line supports various molds to create drainage boards of different thicknesses, hole patterns, and sizes. It meets the needs of different construction and waterproofing applications.

High-Strength Waterproof Performance

The finished drainage boards are resistant to water penetration and corrosion. They provide long-term protection for buildings, tunnels, and roads by efficiently channeling excess water.

Energy-Saving and Cost-Effective

The system optimizes material use and reduces energy consumption. With an efficient heating and cooling system, it lowers operational costs while maintaining high output quality.

Wide Industry Applications

This drainage board manufacturing equipment is used in underground garages, green roofs, metro systems, and road drainage solutions. It enhances water management, prevents seepage, and extends the lifespan of construction projects.

Reliable Production and After-Sales Support

The production line ensures stable, continuous output for large-scale manufacturing. Installation support, training, and a one-year warranty are provided to help maintain long-term performance.

This waterproof board production supplier delivers efficient, automated solutions for the plastic drainage sheet extrusion machine industry. The equipment is ideal for large-scale production, ensuring reliable and high-quality output.

FAQ

Q1: What is the price of a Waterproof Drainage Board Production Line Equipment?

A1: The price depends on automation level, customization, and production capacity. Contact us for a detailed quote based on your specific needs.

Q2: How does a drainage board production line work?

A2: The machine melts plastic materials, extrudes them into sheets, forms drainage patterns, cools them, and cuts them to the desired size automatically.

Q3: What is the production capacity of a drainage board extrusion machine?

A3: Production capacity varies by model and material. Custom configurations are available to meet high-volume manufacturing requirements.

Q4: Can I use recycled plastic for drainage board production?

A4: Yes, HDPE and PP recycled materials can be used, ensuring cost savings and environmental benefits without compromising product quality.

Q5: What are the common applications of drainage boards?

A5: They are used in tunnels, basements, green roofs, road drainage, and waterproofing systems to enhance water management and prevent seepage.

Q6: What certifications do drainage board machines need for export?

A6: Machines typically require CE, ISO, and other regional certifications based on export country requirements. Compliance ensures safe and reliable operation.

Q7: How long does it take to install and start production?

A7: Installation and testing usually take a few days. We provide training and technical support to ensure smooth operation.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province