As the global plastic pipe market continues to expand, the demand for innovative manufacturing processes is more important than ever. One technology that has stood out is the Bellows Production Line, particularly for producing high-precision corrugated pipes. In this article, we will explore how Bellows Production Line offers unmatched advantages in terms of speed, precision, and versatility for producing various types of corrugated pipes like PP/PE/EVA/PVC/PA corrugated pipe.

Overview of the Bellows Production Line

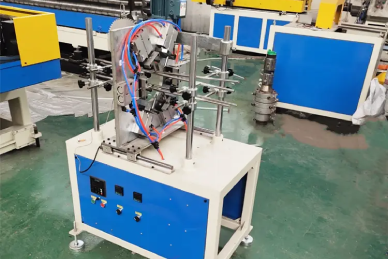

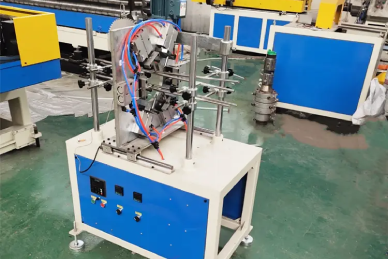

A Plastic corrugated pipe extrusion line for Bellows Production Line is specifically designed to produce corrugated pipes with a variety of thermoplastic materials, including PP/PE/EVA/PVC/PA. The pipes produced on this line are used across multiple industries, including plumbing, drainage, agriculture, and even telecommunications.

Zhongrui’s Plastic Pipe Production Line is one of the leaders in the field, offering advanced technology and high-precision equipment. The company’s production lines are well-suited for both small and large-scale manufacturing, ensuring that the pipes are durable and reliable. With growing global demand for efficient, sustainable piping solutions, Zhongrui’s machinery, including Bellows Production Line, is making waves by producing high-quality products with minimal maintenance.

Key Features of Bellows Production Line

Several technical features distinguish the Bellows Production Line from other types of pipe production equipment:

High production speed in Bellows Production Line – These machines are optimized for fast production, ensuring that businesses can meet high demand without sacrificing quality.

Even corrugated shape from Bellows Production Line – The advanced extrusion technology ensures that each pipe has uniform corrugation, which is crucial for maintaining pressure resistance and durability.

Straight pipe seam in Bellows Production Line – One of the hallmarks of precision in pipe production is the consistency of the pipe seam, which remains straight and even throughout the entire production process.

Smooth surface produced by Bellows Production Line – Pipes with a smooth surface reduce friction, enabling easier flow and minimizing the buildup of debris or scaling over time.

Vacuum pump and vacuum type mould – These machines come equipped with a vacuum pump and vacuum type mould that allow for highly detailed, accurate pipe shapes, including the production of pipes with specialized joints, such as wash basin drain pipes and air conditioner pipes.

Why High-Precision Corrugated Pipes Matter

Corrugated pipes are known for their flexibility, strength, and resistance to environmental factors like corrosion and pressure fluctuations. High-precision pipes manufactured on a Bellows Production Line offer superior structural integrity, which is essential for applications in harsh conditions, such as underground piping for drainage or sewage systems.

The Plastic corrugated pipe extrusion line used in Bellows Production Line ensures that pipes are made to exact specifications, which is crucial for projects that require custom solutions, such as shisha hookah hose pipes or other niche industrial applications. This level of precision reduces the risk of pipe failure, improves operational efficiency, and extends the lifespan of the product.

Technological Advancements in the Plastic Pipe Industry

The plastic pipe market has evolved significantly due to advancements in manufacturing technologies. Companies like Zhongrui have invested heavily in developing high precision production lines that not only meet but exceed industry standards. The integration of advanced technology into the Bellows Production Line allows manufacturers to meet stringent quality requirements while reducing waste and energy consumption.

For example, vacuum type moulds and vacuum pumps play a critical role in shaping pipes to precise dimensions, ensuring that the pipes fit seamlessly in various applications without the need for additional modifications. This is especially beneficial for manufacturers producing corrugated pipe with joint, where the connection points need to be flawless to prevent leaks or structural weaknesses.

Applications of Corrugated Pipes Produced by Bellows Production Line

The versatility of PP/PE/EVA/PVC/PA corrugated pipe produced on a Bellows Production Line makes them suitable for a variety of industries. Let’s explore some of the most common applications.

Water Supply and Drainage Systems

One of the largest markets for plastic pipes is in water supply and drainage systems. Corrugated pipes made using the Bellows Production Line provide superior performance in underground piping due to their strength, flexibility, and resistance to corrosion. The even corrugated shape and smooth surface ensure optimal flow rates, while the durable construction minimizes the need for repairs and maintenance.

Gas Distribution Networks

The gas industry also benefits from high-precision corrugated pipes. Corrugated pipes, particularly those made of PP or PE, offer leak-proof, corrosion-resistant solutions for transporting gases like natural gas and LPG. The straight pipe seam and vacuum type mould ensure a tight seal, reducing the risk of leaks and enhancing safety in gas distribution networks.

Agriculture and Irrigation

In the agricultural sector, corrugated pipes play a critical role in irrigation systems. The flexibility and durability of these pipes allow them to be installed in uneven terrains, adapting to the natural contours of the land. The Bellows Production Line ensures that pipes have a smooth inner wall, which facilitates efficient water flow, leading to improved crop yields and water conservation.

Telecommunications and Cable Protection

Telecommunications companies also rely on corrugated pipes for protecting underground cables. The Bellows Production Line allows for the production of pipes that are flexible yet strong, providing a protective barrier that shields cables from environmental hazards. Wash basin drain pipes and other specialty pipes can be manufactured to custom dimensions, making them ideal for specific industrial applications.

Development Trends in the Plastic Pipe Market

The plastic pipe market is undergoing rapid changes, driven by rising demand in emerging markets and the push for sustainable, energy-efficient solutions. Countries in Asia, Africa, and South America are investing heavily in infrastructure projects, which has led to increased demand for plastic pipes, particularly in water and gas distribution.

Technological advancements have made the production of high precision plastic pipes more efficient and cost-effective. Bellows Production Line is a key player in this transformation, offering high production speed and even corrugated shape with minimal waste. Companies are also focusing on environmentally friendly manufacturing processes, reducing energy consumption while maintaining high product quality.

In terms of competition, the plastic pipe industry is becoming more competitive as new players enter the market with cutting-edge technologies. Established companies like Zhongrui maintain their market share by continually improving their production lines and offering reliable, durable equipment.

Conclusion

The Bellows Production Line stands out as an ideal solution for producing high-precision corrugated pipes. Its advanced features, such as high production speed, even corrugated shape, and the use of vacuum type mould, make it an invaluable tool for industries requiring durable, flexible, and efficient piping solutions.

With its ability to produce a wide range of pipes, from PP/PE/EVA/PVC/PA corrugated pipe to specialized applications like wash basin drain pipes, Bellows Production Line is setting the standard for modern pipe manufacturing. As demand for plastic pipes grows in emerging markets and beyond, companies like Zhongrui will continue to lead the way in providing high-quality, efficient production solutions.

+86-18561886575 (Mr.Wu)

+86-18561886575 (Mr.Wu)

+8618561886575

+8618561886575 238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province

238 Yangzhou West Road, Jiaozhou City, Qingdao City, Shandong Province